Dental implant is a type of dental prosthesis to replace foreign bodies(metal, ceramics, or synthesis material) in edentulous parts and to restore teeth with them as base.

Dental implant care is developing quickly and there have been a lot of studies in the world because requirement for dental implant is increasing nowadays.

Moreover the design of dental implant is one of the main causes of successful implant care.

Most of dental implant is type of screw, and in particular angle, pitch and shape of fixture are very important.

We observed stress distribution of dental implant fixture with change of angle, pitch and shape of fixture thread and so on.

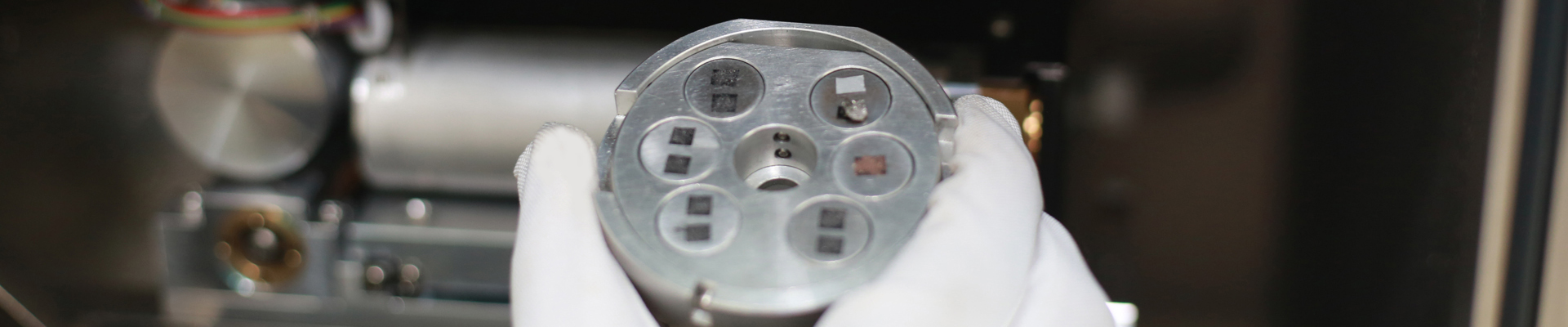

We chose dental implant fixture to Cylinder and Tapper as study group. Control group was included implants of OSSTEM system.

The stress of Cylinder of OSSTEM system was concentrated at the apex of implant fixture on condition of angle 60⁰, pitch 0.8㎜,and constant loading.

At Tapper of OSSTEM system,the stress was concentrated on the initial interface on condition of angle 60⁰, pitch 0.8㎜ and shape of thread of tetragon, and the stress was 8.89MPa at that time.

In study group, first of all, the stress distribution of fixture was observed with change of angle from 50⁰to 70⁰. At this experiment, we found that the stress distribution was the smallest at angle 70⁰.

We observed stress distribution of Cylinder on condition of angle 70⁰ and change of pitch, and when the pitch was 0.8㎜,the stress of interface between implant and bone was 3.72MPa. If the pitch was 1㎜, the stress was 2.81MPa.

We observed stress distribution of Tapper of implant.

On condition of angle 70⁰, pitch 0.8㎜ and thread shape of rectangle, the initial stress of interface was 8.9MPa, while the stress was 7.33MPa on condition of pitch 1㎜.

Finally, we compared study group with control group with change of angle and pitch of Cylinder, and the stress of interface in study group was smaller than one of control group:the stress was 2.81MPa.

The stress of Tapper in study group was smaller than control group and it was 7.33MPa.

We concluded that the stress was the smallest on condition of angle 70⁰and pitch 0.8㎜ in Cylinder and angle 70⁰and pitch 1㎜ in Tapper.