The respected Comrade

"We should make it our major thrust to develop such core, basic technologies as IT, nanotechnology and bioengineering, along with such pivotal and beneficial scientific and technological fields as new materials and energy, space and nuclear technologies, and concentrate our efforts on them."

With the development of science and technology, a number of new functional cosmetics have emerged, and the variety of cosmetics have increased rapidly, adding more importance to the work of analyzing and evaluating their quality in a scientific way.

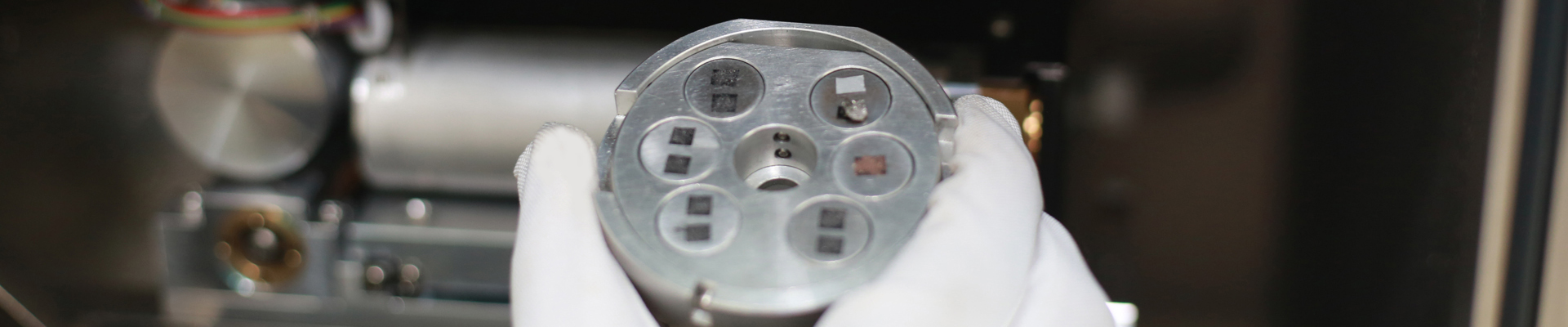

Generally, there are several methods to evaluate the size and shape of powder particles, the scanning electron microscopy (SEM) being one of the most useful instruments.

Recently, researchers of Institute of High-Technology Development Institution,

In the past, SEM was widely used for analyzing cosmetics including eye shadow. In 2007, a researcher characterized the particle size and morphology of a new adsorbent based on pyridine-2,6-diamine-functionalized Fe3O4 nanoparticles using X-ray powder diffraction (XRD), elemental analysis, IR spectroscopy and scanning electron microscopy. In the same year, another researcher reviewed various methods and techniques used to quantitatively determine the geometry of particles. In 2010, the results were evaluated for particle properties, i.e. particle shape (2D and 3D) and particle size (average particle size and particle size distribution) using SEM and image analysis software.

In the above methods, SEM was applied only for the measurement of the total particle size and distribution of the powder particles of various compositions in a sample. However, in color cosmetics such as eye shadow, which consists of mica, kaolin, silicate materials, carbonate (CaCO3, MgCaO3) and metal oxides (TiO2, ZnO, Fe2O3, SiO2) etc., the quality of the product depends on the size and shape of these individual powders.

In this study, we obtained the backscattered electron images and X-ray mapping images (element distribution images) of the eye shadow products using SEM and evaluated the size and shape of individual powder particles according to their composition by applying different techniques.

First, from the results of Monte Carlo simulations we have shown that the backscattered electron coefficient for a powder sample depends not only on the average atomic number of the material, but also on the size and shape of the particle.

Secondly, the particles in the eye shadow were classified into compositions using the backscattered electron images and element distribution images of the SEM.

Third, the identified particles were measured by subdividing them into nine size and five shape indexes according to their composition, and using the established method, the composition-specific particle characterization of four different eye shadow products was carried out.

We report the results of this study in the SCI journal "X-ray Spectrometry" under the title of "Characterization of compositional particles in eye shadow by scanning electron microscope and X-ray mapping"(https://doi.org/10.1002/xrs.3280 2022).