Epoxies have been used widely as structural adhesives due to their superb mechanical properties such as high rigidity, adhesive strength and excellent thermal stability. However, epoxies have the disadvantage of high brittleness, so they can easily break under external impact and pressure. Extensive research has been carried out to overcome this disadvantage by modifying epoxy resin in various ways.

Recently, researchers of the Center for Advanced Technology Research and Development,

In the past, NBR had been widely used to modify epoxy resins, but the miscibility and reactivity of epoxy resin with NBR was poor, so the application was limited. The miscibility and reactivity were improved by adding various functional groups to the NBR rubber. In 2021, a researcher modified Epoxy resin with liquid carboxyl-terminated butadiene acrylonitrile (CTBN) rubber to improve the LSS and T-peel strength by increasing the flexibility of the epoxy resin. In 2016, another researcher also used Hydroxyl terminated polybutadiene (HTPB) liquid rubber to improve the brittleness of epoxy resin.

Carboxylated NBR has good modification effect on epoxy resin but manufacturing cost is high. To reduce the cost, graft copolymerization can be applied. Chromium methacrylate has been used as an adhesion promoter because it has double bonds that can be easily grafted onto the polymer molecule and has functional groups such as carboxyl and hydroxyl groups. Therefore, grafting to NBR and its use in epoxy modification can improve the miscibility and compatibility with epoxy resin and improve the adhesive properties.

In this study, we improved the adhesive properties of modified epoxy–novolac resin by acrylonitrile–butadiene rubber (NBR) grafted poly(chromium methacrylate).

First, we synthesized the Acrylonitrile–butadiene rubber grafted poly(chromium methacrylate) (GNBR) by solution graft copolymerization.

Secondly, we prepared the modified epoxy–novolac adhesive (GNBR–epoxy–novolac resin) by incorporation of GNBR into epoxy–novolac resin.

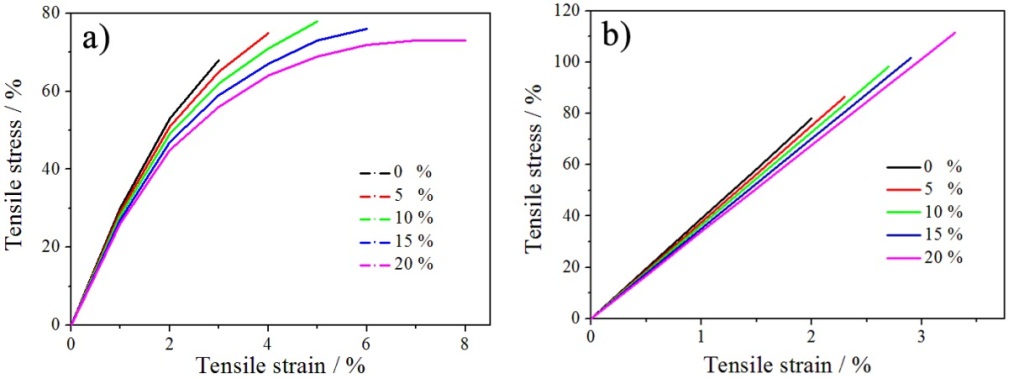

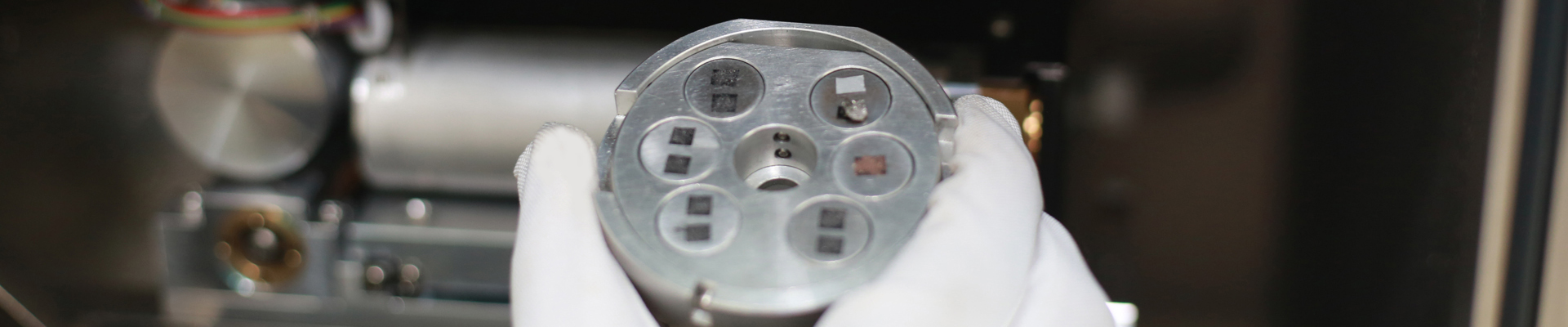

Third, The mechanical properties of GNBR–epoxy–novolac resins at both room temperature and 233 K were tested.(Fig.) The tensile strength, Young's modulus and failure strain of GNBR–epoxy–novolac resins were estimated from the tensile stress–strain curves and the lap shear strength (LSS) were evaluated using aluminum adherents, and the results showed that they were significantly improved.

The results have been published in "RSC Advances" under the title of "Improvement of adhesive properties of modified epoxy–novolac resin by acrylonitrile–butadiene rubber grafted poly (chromium methacrylate)"(https://doi.org/10.1039/d4ra05047a).