Chairman

"Primary emphasis in the scientific research work of universities should be laid on enriching the contents of education and enhancing their qualities and at the same time, on finding solutions to the theoretical and practical problems and scientific and technological problems arising in the revolution and construction, developing basic scientific subjects and pioneering new spheres of scientific and technological sectors."

Research laboratory of functional chemical materials, Institute of Applied Chemistry, Faculty of Chemistry,

Organo-phosphorus flame retardant, RDP (resorcinol diphenyl phosphate) was synthesized from resorcinol, phosphorus oxy-chloride and phenol, then it was used for preparation of flame retardant polyethylene resin.

Polyethylene (PE) has high processibility, mechanical properties, chemical resistance and wear resistance, but it is limited to its application due to a high flammability.

Flame retardant, RDP is one of the promising flame retardants for flame retardant processing of plastic materials due to its much lower environmental impact and high flame retardant effect compared with halogen flame retardants.

The difficulty in mixing RDP with PE resin is that they are not well inter-dispersed mutually because PE resin is non-polar.

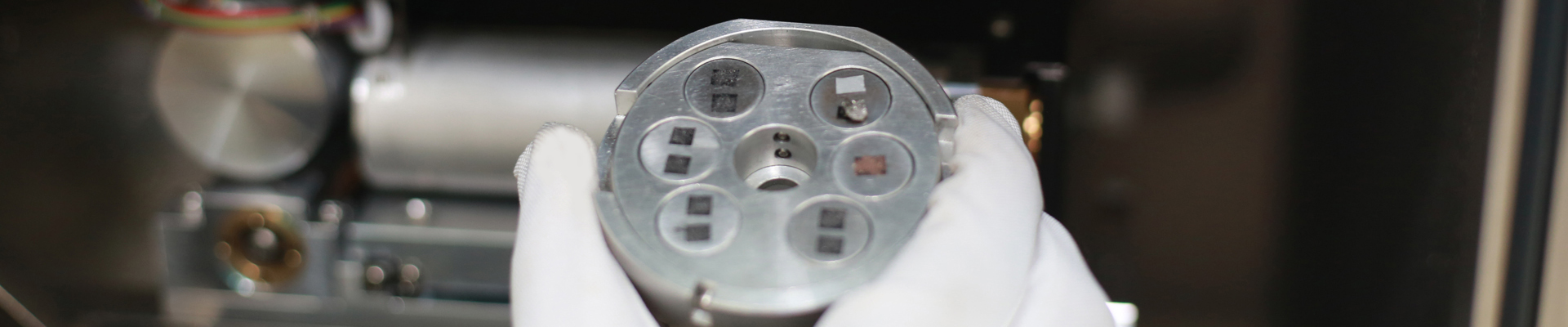

To solve this problem, in the functional chemical materials research laboratory of the Institute of Applied Chemistry, they microencapsulated flame retardant RDP with urea-formalin resin to resinite the surface of flame retardant micro-particles, resulting in compatibility with PE resin, then the flame retardant composite materials were prepared.

The formation temperature and pH of the pre-polymer solution, pH of the encapsulation polymerization reaction and temperature, which are important factors in the microencapsulation of the flame retardant RDP, were elucidated and the particle size distribution of the obtained microcapsules was confirmed.

The flame-retardant PE resin composites were prepared by melt mixing of the microencapsulated RDP, red phosphorus and flame retardant synergist Mg(OH)2 with PE resin and discussed the flame retardant level, thermal stability and flame retardant mechanism through vertical flame test, LOI measurements, FT-IR, TGA and SEM analyses.

When the content of microencapsulated RDP, red phosphorus and flame retardant Mg(OH)2 in PE resin composite were 20, 10 and 5%, respectively, the flame retardant resin composite reached UL 94 V-0 level and LOI value was 29.6%.

The capsule core material RDP and the capsule shell, material urea-formalin resin, acted as an intumescent flame retardant with P-N flame retardant synergism and inhibited the combustion process by forming a char layer with a high barrier effect against heat and oxygen.

In October 2022, the results of the above study were published on "Polymer Bulletin" under the title of "Preparation and flame retardance of polyethylene composites with microencapsulated resorcinol bis(diphenyl phosphate), red phosphorus and magnesium hydroxide"(https://doi.org/10.1007/s10847-022-01135-4).